Training Within Industry and its modules Job Instructions, Job Relations, and Job Methods are well known. But (thanks to Mark Warren) I just recently learned about another module: Job Instructions for Second-Line Supervisors (nowadays called managers). This is a hierarchy level higher, and the goal is to support and guide the shop floor supervisors on how to use job instructions. Let me dig deeper:

Training Within Industry and its modules Job Instructions, Job Relations, and Job Methods are well known. But (thanks to Mark Warren) I just recently learned about another module: Job Instructions for Second-Line Supervisors (nowadays called managers). This is a hierarchy level higher, and the goal is to support and guide the shop floor supervisors on how to use job instructions. Let me dig deeper:

Introduction

I have written extensively on Training within Industry, including the modules on Job Instructions (JI), Job Relations (JR), and Job Methods (JM). It is an old program from World War II, but the content is still highly relevant today, and I believe the guidelines are very helpful. The job instructions are designed to teach workers how to follow a standard. Below is the original World War II Job instruction card from the War Manpower Commission. Oldie but goldie.

Job Instructions for Second-Line Supervisors

The Training Within Industry program also published a lesser known set of guides for second-line supervisors (i.e. the people one level above the first line supervisors). Nowadays this would be the first level of management over the shop floor supervisors, and in this post I will simply call them managers to avoid confusion. This guide for manager job instructions is called Using Job Instructions and helps the manager to have the supervisors in his group both a) start using job instructions, and b) continue using job instructions.The manager also receives coaching on how to do proper the second level supervision for Training Within Industry.

The supervisor is in charge of both training his operators in job instructions and making sure they follow the job instructions guide. Below is the original World War II Using Job Instructions card for managers. For easier reading, the text is also copied below the card, but I will go through each point in more detail.

How to START Your People Using It

- HELP them spot production needs and work out a training schedule to meet the needs—TIME TABLE.

- HELP them dig out the key points that cause scrap, accidents, rejects and delays—JOB BREAKDOWNS.

- ENCOURAGE them to have everything ready and the work place properly arranged.

- GIVE them practice in putting across the instruction as organized on their job breakdowns-4 STEPS.

How to KEEP Your People Using It

- REVIEW with them their time tables once a [___]. Make sure current production needs are spotted.

- REVIEW with them the job breakdowns they will use during the [___]. Look for the key points that will prevent scrap accidents and delays.

- CHECK workers occasionally to see if they know the key points.

- Look into injuries, scrap, rejects, tool and equipment damage. Find the cause: 1) Was a key point left out of the breakdown? 2) Were the four steps poorly used? Coach where needed.

These bullet points alone may be a bit confusing. Hence, let me explain the individual steps of the two sides of both cards. Overall, this Using Job Instructions card for the manager is not as straightforward and easy-to-use as the Job Instructions card for the supervisor.

How to START Your People Using It

1) TIME TABLE: The time table is related to the qualification matrix… except that for a blank spot there may be a date for when each worker should be trained. But not everybody needs to be skilled at everything, and it is also necessary to decide who should be trained in what (i.e., to “spot production needs”). The manager instructs and guides the supervisor on creating such a timetable. Below is an original Training Within Industry example.

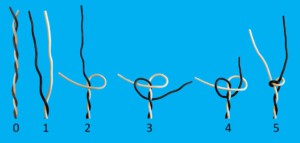

2) JOB BREAKDOWNS: Next, the manager instructs the supervisor on how to do job breakdowns—which is crucial for creating good work standards. The example in the original literature is teaching them a knot (fire underwriter knot). The Training Within Industry trainer trains the manager to teach the manager how in turn to train the supervisor on creating a job breakdown. In a full Training Within Industry workshop, the trainer instructs the manager on coaching supervisors. This also follows the typical job instruction steps, where the trainer first demonstrates a coaching of a supervisor for the manager and then observes the manager coaching another supervisor. For this I even have a detailed original plan from World War II.

3) Encourage: The manager should make sure the supervisor provides a clean workplace for his operators, and that they have all the necessary tools. Nowadays we would call this 5S. The supervisor should set a good example here for the operator.

4) 4 Steps: This is probably the most confusing step of the standard. This refers to the original job instruction card for the supervisor. The manager should go with the supervisor through all 4 steps: 1) Prepare the Worker; 2) Present the Operation; 3) Try Out Performance; and 4) Follow Up. For details on these 4 steps, check out my post on Job Instructions (for supervisors).

How to KEEP Your People Using It

The steps on the other side of the Using Job Instructions card help the manager to follow up on the coaching of the supervisor. This would be similar to the Check and the Act of the PDCA circle. The manager should of course regularly review the training timetables as well as the job breakdowns. The card actually does not give a suggested interval, as this depends somewhat on the production system. Hence, it is up to the manager to decide, giving him more freedom on how to manage his domain. However, it is suggested to review both once per week. The verification if the supervisor knows the key points should also be done occasionally, albeit no frequency is given or even suggested.

Interesting is the last point on looking into injuries, scrap, rejects, tool and equipment damage. This is now pushing to continuous improvement. The manager should be on the lookout for improvement potentials. I particularly liked that safety is mentioned first! It also gives a guide on how to improve such shortcomings, and this is by working with a standard. If there is a problem (safety, quality, waste, etc.), either the standard (the key points) is not good enough and should be improved, or the key points were not followed properly. In either case the manager should coach the supervisor on how to improve the key points to prevent further occurrence of the problem, or coach the supervisor on how to properly coach and train his operators so that they follow the standard correctly. This is just as we would do kaizen nowadays through the use of standards.

In any case, I hope this article was interesting to you. Now, go out, make sure your subordinates know how to instruct their own subordinates, and organize your industry!

PS: Many thanks to Mark Warren for his never-ending knowledge on all things related to Training Within Industry!

Thank you for the post. From personal experience the training identified provides the foundation of excellence for any company. This recognizes where the value add the customer wants is located: on the factory floor. Too many companies view production employees is a necessary evil that needs to be reduced.